Chemical sector – Understanding hazards and protection for workers

Chemical sector – understanding hazards and protection for workers

In the chemical sector, where hazardous materials are handled daily, even a minor problem can lead to major risks. An experienced process operator at a busy factory discovered an unusual odor one day and experienced mild eye irritation during routine checks. What seemed like a minor anomaly turned out to be a serious problem when it was discovered that an extraction system was leaking. Thanks to the employee’s quick response, more serious consequences were avoided. This situation shows how important it is to be vigilant at all times.

In this article, we focus on chemical hazards in the chemical sector. We explain what chemical hazards entail, identify the five most common types, and provide advice on how to protect against them. Finally, we make recommendations for appropriate PPE to ensure worker safety.

What are chemical hazards?

Chemical hazards are the risks created by the use, storage, production, or processing of chemicals. These hazards can lead to serious health effects, accidents, and environmental damage. Understanding and managing these hazards is important for ensuring a safe work environment and reducing risks to both people and the environment.

Types of chemical hazards

There are several chemical hazards in the chemical sector. We focus on the five most common, give an example for each, evaluate the degree of dangerousness and the impact they can have on workers.

- Toxicity:

-

- Exposure to toxic substances can cause both acute and chronic health effects, such as poisoning, respiratory problems, and long-term organ damage or cancer (RIVM, 2023)

- Example: Benzene is a chemical used in the production of plastics, resins, and synthetic fibers

- Degree of dangerousness: very dangerous ⚠️⚠️

- Corrosivity:

-

- Corrosive substances can cause severe burns on skin contact and damage to eyes and respiratory tract when vapors are inhaled (Arboportaal, s.a.)

- Example: Sulfuric acid is widely used in the chemical industry, for example in the production of fertilizers

- Degree of dangerousness: very dangerous ⚠️⚠️

- Flammability:

-

- Chemicals that easily catch fire pose a high risk of fires and explosions

- Example: Acetone is a widely used solvent in the chemical industry and in laboratories

- Degree of dangerousness: high danger ⚠️

- Explosiveness:

-

- Substances that can explode under certain conditions pose a serious physical hazard to employees

- Example: Ammonium nitrate is used as fertilizer and in explosives

- Degree of dangerousness: very dangerous ⚠️⚠️

- Chemical Reactivity:

-

- Highly reactive substances can cause unexpected reactions when in contact with other chemicals or with water, leading to hazardous conditions such as explosions or the release of toxic gases

- Example: Sodium is a highly reactive metal often used in the chemical industry

- Degree of dangerousness: high danger ⚠️

How do you protect yourself from these substances?

Protection from chemicals in industry requires a combination of measures to ensure safety and the use of appropriate PPE. The choice of PPE should always be based on a risk assessment of the specific working conditions and the properties of the chemicals being worked with. It is essential that PPE be used and maintained correctly to ensure maximum protection.

Below we share the most common PPE in this industry and the associated safe work procedures:

PPE

- Respiratory protection:

- Gas and vapor masks: for protection from harmful gases and vapors

- Dust masks: for protection from inhalation of hazardous substances such as powders or fibers

Our recommendations:

The 3M visor helmet is combined with the 3M Versaflo motor-powered system that is suitable for use in an ATEX environment and provides long-lasting and optimal protection for the respiratory tract, head and face.

|

|

|

| 3M M-306 VISOR HELMET Art. No.: 4.38.520.00 |

3M VERSAFLO TR-819E STARTER KIT Art. No.: 4.38.580.00 |

MOLDEX 255501 DUST MASK FFP3 NR D WITH EXHALATION VALVE Art. No.: 4.82.555.00 |

- Eye protection:

- Safety glasses: for protection from chemical splashes or dust particles

- Face shields: for protection from larger amounts of liquids or as additional protection on top of safety glasses.

Our recommendation:

|

| UVEX ULTRASONIC 9302-285 WIDE-VIEW GOGGLES Art. No.:7.17.589.00 |

- Hand protection:

-

- Chemical-resistant gloves: made of materials such as nitrile, neoprene, or butyl rubber, depending on the nature of the chemicals being worked with

Our recommendations:

|

|

| OXXA® X-PRO-CHEM 51-900 Art. No.: 1.51.900.00 |

ANSELL ALPHATEC SOLVEX 37-900 Art. No.: 1.90.377.00 |

- Body protection:

-

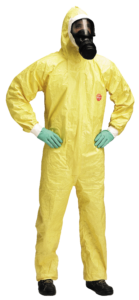

- Parka: provides light protection and resists splashes of liquids, making it suitable for everyday use in environments where the risk of chemical exposure is minimal. However, more intense or high-risk chemical work requires specialized protective clothing.

- Coverall: which is specially designed to withstand the specific chemicals being worked with. The coverall provides full body coverage and protection from chemical exposure, which is essential for working safely in high-risk environments.

Our recommendations:

|

|

| SIOEN 7223 HEDLAND PARKA Art. No.: 2.60.572.00 |

DUPONT TYCHEM 2000 C OVERALL Art. No.: 2.67.442.00 |

- Foot Protection:

-

- Safety shoes: with steel toecap and chemical-resistant material, are suitable for everyday use

- Safety boots: provide extra protection for specific higher-risk tasks, such as working with larger amounts of chemicals or in areas with high splash

Our recommendations:

|

|

| EMMA BILLY SAFETY SHOE S3 Art. No.: 5.93.330.00 |

DUNLOP JOBGUARD FULL SAFETY BOOT S5 Art. No.: 5.26.226.00 |

- Hearing protection:

-

- Earplugs or earmuffs: If the noise level in the workplace is high, such as from the use of machinery.

Our recommendations:

|

|

| uvex X-FIT 2112-001 EARPLUG Art. No.: 3.17.205.00 |

MSA V-GARD HIGH EAR MUFF WITH HELMET ATTACHMENT Art. No.: 3.17.132.00 |

- Head protection:

- Safety helmets: To protect against falling objects or as protection when working in explosive environments.

Our recommendation:

|

| MSA V-GARD 500 UNVENTILATED SAFETY HELMET Art. No.: 6.16.867.00 |

Safe Work Procedures

- Training and Education: ensure that all employees are well versed in proper chemical handling procedures, including the use of PPE and emergency procedures

- Safe Storage: store chemicals in approved, labeled containers in safe, well-ventilated locations according to manufacturer’s recommendations and laws and regulations

- Proper Use: follow all chemical use instructions and avoid unnecessary exposure by using safe work practices

Need help?

Would you like advice or additional information on suitable products for use in the chemical sector? Contact us today on T. +31 (0)181 47 50 00. Our enthusiastic team will be happy to tell you more!